- Dip phosphatizing for coating primer

- Spray phosphating for coating primer

- Rust-proof treatment

- Sliding wear-resistant treatment

- Lubricating treatment for plastic processing

- Primer treatment and rust-proof treatment for aluminium coating

- Associated products

- Function treatment for hot galvanized steel

- Function treatment for electro-galvanized steel sheet

- Primer treatment for color steel

- Cold-rolled rolling oil

- Other

- Hydrophilicity of evaporator for vehicle

- Magnesium alloy treatment

Product

Function treatment for hot galvanized steel

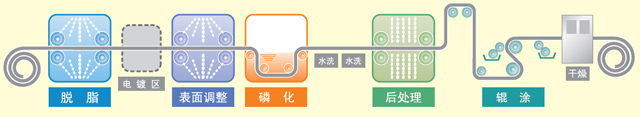

1.Process drawing

2.Examples

| Functions | Surface treatment type | Electroplating type | Degreasing | Surface conditioning | Parkerising | After treatment | Roller painting |

| Passivation | Chromium coating | Zinc plating |

FC-4370 FC-D5400 series |

ZM-3360 | ZM-3360H | ||

| Hot dip, 5% aluminium | ZM-3391 | ZM-3391 | |||||

| Hot dip, 5% aluminium | ZM-3398 | ||||||

| 55% aluminium | ZM-R1415A | ||||||

| Chromium-free | Zinc plating | CT-E300 series | |||||

| Inorganic fingerprint resistance | Chromium coating | Zinc plating | ZM-3383 | ||||

| Light lubrication | Chromium-free | 55% aluminium | CT-E360 series | ||||

| Parkerising for lubrication | Zinc phosphate | Alloying | PL-Z |

| Functions | Process | Product name (ellipsis) | Treatment condition | Features | ||||

| Method | Temperature (℃) | Time (min) | Coating modulus (mg/m2) | PMT(℃) | ||||

| Cleaning before electroplating | Degreasing | FC-4370 |

Spray Soak |

60~90 | 2~10 | - | - | Strongly basic powdery degreaser |

| Degreasing | FC-D5400 series |

Spray Soak Electrolysis |

60~90 | 2~10 | - | - | Strongly basic powdery degreaser | |

| Degreasing | AD-4828 |

Spray Soak Electrolysis |

60~90 | 2~10 | - | - | Degreasing additive (Powder) | |

| Degreasing | AD-4945 |

Spray Soak Electrolysis |

60~90 | 2~10 | - | - | Degreasing additive (Powder) | |

| Passivation | After treatment | ZM-3360H | Spraying, roller painting | Normal temperature~50 | 1~5 | Cr10~30 | 60~80 | Chromium passivation for hot galvanizing |

| After treatment | ZM-3391 | Spraying, roller painting | Normal temperature~50 | 1~5 | Cr10~30 | 60~80 | Chromium passivation for hot galvanizing | |

| Roller painting | ZM-3398 | Roller painting | Normal temperature | - | Cr10~30 | 60~80 | Chromium passivation for hot galvanizing | |

| Roller painting | ZM-R1415A | Roller painting | Normal temperature | - | Cr10~30 | 60~80 | Chromium passivation for 55% aluminium galvanizing | |

| Roller painting | CT-E300 series | Roller painting | Normal temperature | - | 0.3~1.2g/m2 | 60~120 | Chromate-free passivation | |

| Inorganic fingerprint resistance | Roller painting | ZM-3383 | Roller painting | Normal temperature | - | Cr20~60 | 60~100 | Inorganic fingerprint-resistant chromium |

| Light lubrication | Roller painting | CT-E360 | Roller painting | Normal temperature | - | 1.5~2g/m2 | 60~120 | Chromium-free for 55% aluminium galvanizing |

| Parkerising for lubrication | Surface conditioning | PL-Z | Spray | Normal temperature~40 | 1~2 | - | - | Ti collloid series |

| Parkerising |

Spray Soak |

50~60 | 2~12 | 0.5~1.5g/m2 | - | For GA and EG lubrication | ||

Formed products

| Functions | Process | Product name (ellipsis) | Treatment condition | Features | ||||

| Method | Temperature (℃) | Time (min) | Coating modulus (mg/m2) | PMT(℃) | ||||

| Passivation | After treatment | LN-E5100 series | Soak | 60 | 30~40 | 400~500 | Floor heat | Chromium-free |

| Roller painting | LN-E5100 series | Flow coating, and etc. | Normal temperature | - | 2~3g/m2 | 90~100 | Chromium-free | |

| 【Return】 |