- Dip phosphatizing for coating primer

- Spray phosphating for coating primer

- Rust-proof treatment

- Sliding wear-resistant treatment

- Lubricating treatment for plastic processing

- Primer treatment and rust-proof treatment for aluminium coating

- Associated products

- Function treatment for hot galvanized steel

- Function treatment for electro-galvanized steel sheet

- Primer treatment for color steel

- Cold-rolled rolling oil

- Other

- Hydrophilicity of evaporator for vehicle

- Magnesium alloy treatment

Product

Lubricating treatment for plastic processing

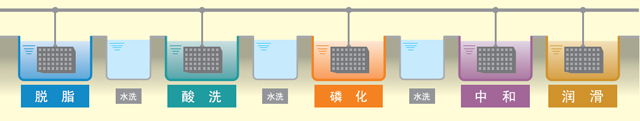

1.Process drawing

2.Examples

| Uses | Degreaser | Pickling agent | Phosphatizing agent | Neutralizer | Lubricant |

| Single-process lubricating treatment for cold forging | - | Sand blasting and polishing | - | - | FL-E700 series |

| Lubricating treatment for cold forging | CL-357 | Hydrochloric acid | PB-181X | PL-21 | LUB-4618 |

| Single-process lubricating treatment for drawing | - | Sand blasting and polishing | - | - | FL-E875 |

| Lubricating treatment for drawing | - | Hydrochloric acid | PB-421WD | - | - |

| Lubricating treatment for tubing | FC-4360 | Sulfuric acid | PB-181X | PL-21 | LUB-4618 |

| Lubricating treatment for crude steel wire | - | Hydrochloric acid, sulfuric acid | PB-3670X | PL-21 | LUB-4618 |

3.Degreaser

| Degreaser | Type | Treatment | Temperature (℃) | Time (min) | Features |

| Strong base | Soak | 80~90 | 5~10 | Contains NaOH, can remove LUB lubricant | |

| FC-4360 | Strong base | Soak | 55~65 | 5~10 | Strong cleaning power, can remove LUB lubricant |

4.Phosphatizing agent

| Phosphatizing agent | Material | Treatment | Temperature (℃) | Time (min) | Adhesion amount (g/m2) | Features |

| PB-9X | Iron steel | Soak | 80~90 | 20~60 sec. | 5~8 | In inline, zinc phosphate coating |

| PB-181X | Iron steel | Soak | 70~80 | 3~10 | 5~10 | Zinc phosphate coating |

| PB-421WD | Iron steel | Soak | 70~80 | 3~10 | 5~10 | Zinc phosphate coating |

| PB-3670X | Iron steel | Soak | 80~85 | 5~10 | 5~8 | Zinc calcium phosphate coating, with favorable heat stability |

| Iron steel | Soak | 70~80 | 3~10 | 5~8 | Low slag type | |

| Iron steel | Soak | 50~60 | 20~60 sec. | 4~8 | In low temperature type inline | |

| PB-EL905 |

Steel, stainless steel |

Soak | 80~85 | 1~5 sec. | 1~40 | In inline, no slag. |

| FB-A | Stainless steel | Soak | 90以上 | 10~20 | 10~20 | Standard agent for oxalate film and stainless steel |

| FB-3803 | Stainless steel | Soak | 85~95 | 5~15 | 10~20 | Suitable for SUS400 series ferrate series stainless steel |

| Stainless steel | Soak | 80~90 | 15~20 | 10~20 | Suitable for SUS300 series austenitic stainless steel | |

| PM-3851 | Titanium | Soak | 60~65 | 3~10 | 20~40 | Suitable for plastic processing pure titanium |

| AB-A | Aluminium | Soak | 98以上 | 1~5 | 5~10 | Suitable for cold forging aluminium |

| PB-L3696X | Steel | Soak | 70~80 | 2~10 | 5~10 | Suitable for cold working and drawing |

5.Neutralizer

| Neutralizer | Type | Treatment | Temperature (℃) | Time (min) | Features |

| PL-21 | - | Soak | Normal temperature~80 | 1~5 | Neutralizer after phosphate and oxalate treatment |

6.Lubricant

| Lubricant | Type | Treatment | Temperature (℃) | Time (min) | Adhesion amount (g/m2) | Features |

| FL-E740 | Single-process lubricant | Soak | 40~70 | Above 1 sec. | 5~15 | Substitute of PB and LUB |

| FL-E760 | Single-process lubricant | Soak | 40~70 | Above 1 sec. | 5~15 | Substitute of PB and LUB |

| FL-E739 | Single-process lubricant | Soak | 40~70 | Above 1 sec. | 5~15 | Substitute of PBh and LUB |

| FL-E875 | Single-process lubricant | Soak | 40~70 | Above 1 sec. | 5~15 | Substitute of zinc phosphate coating. |

| LUB-CA02 | Lime soap | Soak | 50~60 | Above 2 | 5~15 | In lime soap |

| LUB-235 | Sodium stearate | Soak | 70~85 | 3~5 | 2~5 | Standard lubricant for plastic processing |

| LUB-4618 | Sodium stearate | Soak | 70~85 | 3~5 | 2~4 | For cold forging |

| Sodium stearate | Soak | 70~85 | 3~5 | 2~4 | For crude steel wire | |

| Molybdenum disulfide | Soak | 60~80 | 1~5 | 10~20 | Water-based MoS2 lubricant | |

| Oil system |

Soak |

65~70 |

5~20 |

5~10 |

Reaction type oil system lubricant. |

7.Coating remover

| Coating remover | Type | Treatment | Temperature (℃) | Time (min) | Features |

| Medium alkali | Soak | 60~95 | 1~10 | To remove LUB | |

| CL-357 | Strong base | Soak | 80~95 | 5~10 | To remove LUB |

| FC-4345 | Strong base | Soak/Spray | 60~90 | 1~10 | To remove LUB |

| CL-2074 | Strong base | Soak | 93~99 | 3~10 | To remove LUB |

| 【Return】 |