- Dip phosphatizing for coating primer

- Spray phosphating for coating primer

- Rust-proof treatment

- Sliding wear-resistant treatment

- Lubricating treatment for plastic processing

- Primer treatment and rust-proof treatment for aluminium coating

- Associated products

- Function treatment for hot galvanized steel

- Function treatment for electro-galvanized steel sheet

- Primer treatment for color steel

- Cold-rolled rolling oil

- Other

- Hydrophilicity of evaporator for vehicle

- Magnesium alloy treatment

Product

Sliding wear-resistant treatment

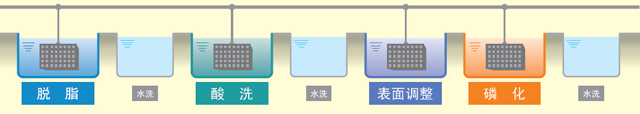

1.Process drawing

2.Examples

| Uses | Degreaser | Pickling agent | Surface regulator | Phosphatizing agent |

| Common treatment | FC-4360 | Hydrochloric acid | PL-VM | PF-M1A |

3.Alkaline degreaser

| Degreaser | Type | Treatment | Temperature (℃) | Time (min) | Features |

| FC-4360 | Strong base | Soak | 55~65 | 5~10 | Strong cleaning power, standard degreaser |

4.Surface regulator

| Surface regulator | Type | Treatment | Temperature (℃) | Time (min) | Features |

| PL-VM | Manganese phosphate | Soak | Normal temperature | 1~3 | Standard surfactant |

| PL-55 | Manganese phosphate | Soak | Normal temperature | 1~3 | In fine surfactant |

| PL-35 | Manganese phosphate | Soak | Normal temperature | 1~3 | In fine surfactant |

5.Wear-resistant, sliding soak phosphatizing agent

| Phosphatizing agent | Type | Appearance | Treatment | Temperature (℃) | Time (min) |

Adhesion amount (g/m2) |

Features |

| PF-M1A | Manganese sulfate | Grey black | Soak | 95~99 | 10~15 | 10~15 | Abrasion performance of mechanical part |

| PF-M2A | Manganese sulfate | Grey black | Soak | 95~99 | 15~30 | 5~15 | Abrasion performance of mechanical part |

| PF-M5 | Manganese sulfate | Grey black | Soak | 80~90 | 5~15 | 5~9 | Wear-resistant film type, to use with accelerator |

| Manganese sulfate | Grey black | Soak | 70~80 | 10~15 | 10~15 | Wear-resistant, low temperature type | |

| PF-M5004 | Manganese sulfate | Grey black | Soak | 95~99 | 2~5 | 1.5~6 | Wear-resistant, thin-film type |

| 【Return】 |